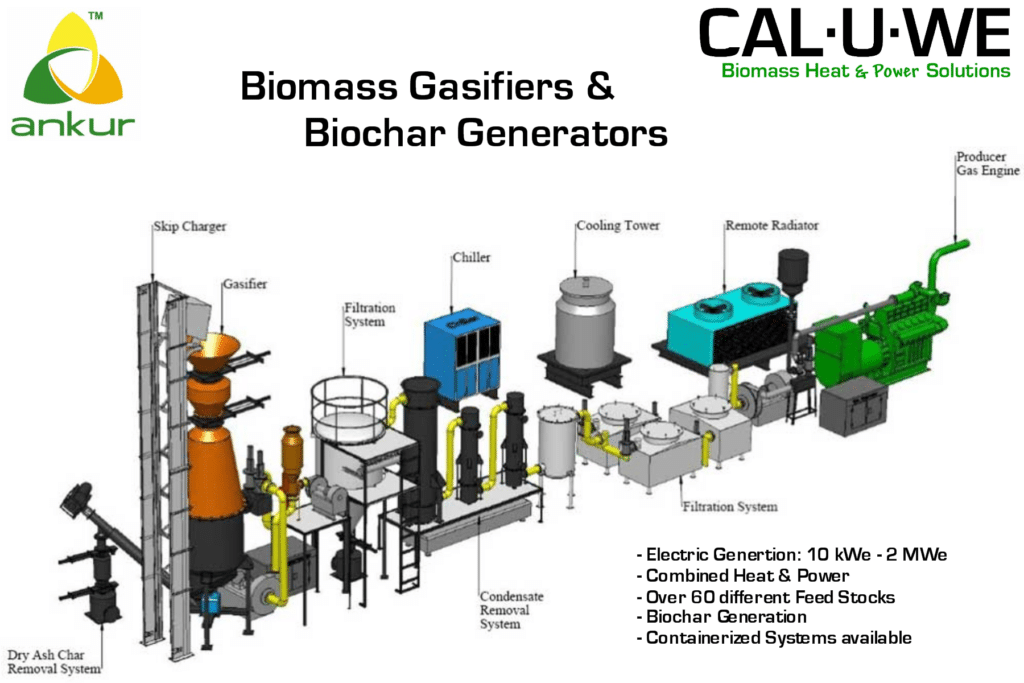

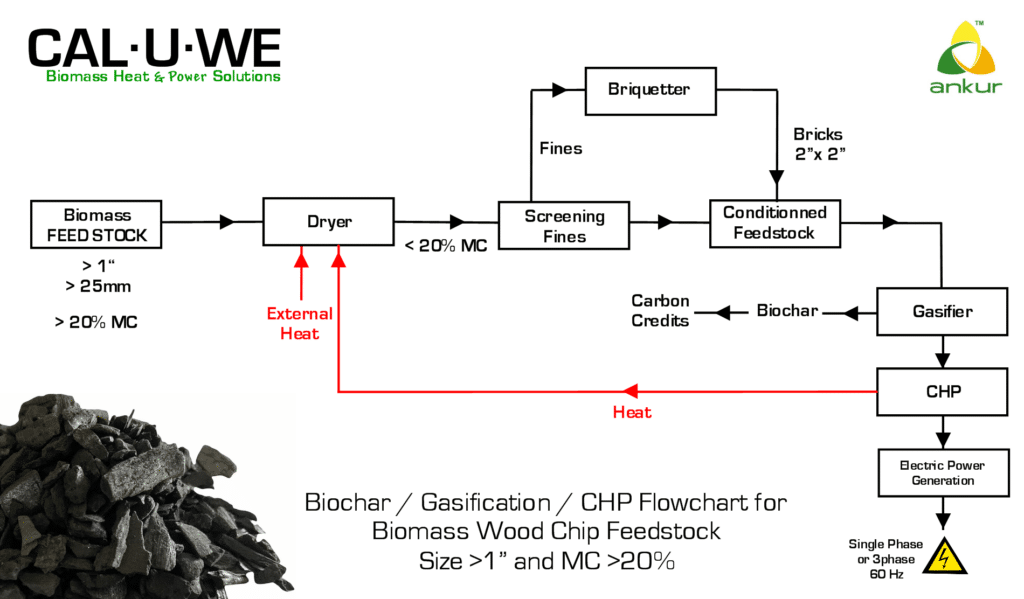

The biomass power plants from ANKUR generates Electricity, Heat and Biochar according to the principle of combined heat and power (CHP). The biomass power plant consists of a biomass gasifier and the combined heat and power unit (CHP). The generated power will either be consumed by the owner or sold into the grid. The heat generated during the process can be used for the heating of buildings, for drying grain and biomass or in district heating systems. ANKUR biomass power plants only use biomass for power generation and convert locally sourced biomass or organic wastes into clean, efficient energy.

1. Feed of fuel at biomass power plant

The skip charger from ANKUR automatically transports the fuel (biomass) from the fuel bunker to the biomass power plant. An integrated metal interceptor in the fuel sewer port separates foreign material. A second conveyor screw transports the biomass to the reformer of the wood gasifier unit.

2. Reformer in wood gasifier for clean wood gas

The reformer is the heart of the biomass power plant. It produces almost tar-less wood gas from biomass in a controlled process, which works on the downdraft principle: the wood chips and the wood gas moves in the same direction. The innovative structure of the reformer offers high fuel flexibility. Using a compact fire bed with temperature monitoring, we guarantee a regulated wood gas production that ensures the efficiency of our biomass power plant. With our patented and proven biomass gasification technology we produce an extremely clean wood gas, which we can prove.

3. Wood gas filter at wood gasifier unit

The produced wood gas is cooled by the heat exchanger and passes through a wood gas filter with integrated self-cleaning at the gasifier unit. ANKUR biomass power plants have a second wood gas filter (emergency filter) for optimal plant secure. The cooled wood gas passes through two filter systems, before it drives a powerful engine, which produces the electricity and heat.

4. Efficient wood gas CHP

The solid gas engine burns the wood gas and converts the energy of the wood gas into kinetic energy. A powerful natural gas generator transforms the rotation into electricity. In addition the wood gas CHP produces heat, which makes the whole process highly efficient.

Available models:

- PG-100 30 kWe / xx kWt

- PG-200 60 kWe / xx kWt

- PG-350 60 kWe / xx kWt

- PG-400 120 kWe / xx kWt

- PG-850 250 kWe / xx kWt

- PG-1250 375 kWe / xx kWt

- PG-1500 450 kWe / xx kWt

- PG-2200 640 kWe / xx kWt

- PG-2500 750 kWe / xx kWt